Customized Stone Crushing Solutions in AIMIX Group

Essential Tips for Construction Waste Recycling: Preventing 50% Concrete Crusher Loss in Iron Removal Before Crushing

When it comes to construction waste recycling, particularly with concrete materials, one silent yet costly mistake continues to drain productivity: improper iron removal before the crushing process. Across numerous job sites, up to 50% of concrete crushers' efficiency loss is traced back to ferrous contamination. Hidden within slabs, rebar, bolts, and other embedded metals often go undetected and damage the crushing equipment, halt operations, and compromise output quality. Fortunately, there are strategic ways to prevent this waste and protect both machinery and margins.

Understanding Why Iron Removal Is Critical

Reinforced concrete often contains significant volumes of steel, mesh, or embedded fixtures that can wreak havoc on crushers if not extracted beforehand. When ferrous metals enter the crusher chamber, they not only wear down key components like rotors and jaws but also pose severe risks to the conveyor belts, screens, and discharge systems. These interruptions lead to unplanned downtime, costly maintenance, and an overall drop in crushing efficiency.

Moreover, damaged equipment doesn’t just impact output—it can create safety hazards and legal liabilities on site. Taking proactive steps to remove iron early ensures safer operation and prevents waste accumulation that clogs up the recycling loop.

Integrate Smart Magnetic Separation Systems

Use multi-stage magnetic separation for layered protection

Installing a multi-layer magnetic separation system is one of the most effective ways to capture metal contaminants before they reach the crusher. Start with an over-belt magnetic separator to catch surface-level rebar and bolts. Then, integrate drum or pulley magnets for finer scrap that might be embedded deeper within the material stream. These stages act like filters, removing metals at varying depths and sizes.

Modern systems also come with automatic discharge mechanisms, so the removed metal doesn't just collect—it gets separated and stored, ready for construction waste recycling or resale.

Combine with eddy current separators for non-ferrous particles

Don’t just focus on ferrous metals. Construction waste can also contain aluminum, copper, or zinc. By placing eddy current separators downstream from the magnetic equipment, the system can isolate and extract non-ferrous particles—boosting recovery rates and reducing wear on downstream crushers and screens. This dual strategy increases overall throughput and protects investments in crushing machinery.

Train On-Site Teams to Spot and Sort Early

Manual pre-sorting still matters

While automation plays a big role, trained eyes on the ground are invaluable. Encourage workers to manually inspect large concrete pieces before they enter the hopper. Visible rebar, piping, or embedded fasteners should be removed by torch-cutting or hammering out. Create designated sorting zones with safety gear and signage to streamline this process without slowing operations.

A team that understands the why behind metal removal will take extra care in ensuring only clean materials feed the crusher. Conduct short toolbox talks or on-site workshops to reinforce these practices consistently.

Equip demolition teams with metal-aware tactics

Much of the metal contamination stems from the demolition phase. Provide demolition crews with proper tools and cutting plans to minimize embedded steel left in slabs. Simple practices like wire cutting before breaking or using magnetic grapples during dismantling can save hours of metal sorting later. It's about building awareness into the full lifecycle of waste handling.

Monitor and Maintain Separation Systems Regularly

Magnetic and eddy current systems, like all machines, require routine maintenance to stay effective. Accumulated debris, worn magnets, or misaligned conveyors can all reduce separation efficiency over time. Schedule weekly checks for magnet strength, sensor calibration, and alignment of feed chutes.

Consider installing sensor-based alerts for critical failure points—such as when iron slips past a separator into the aggregate crusher machine. These early warnings provide precious time to intervene before damage is done.

Construction waste recycling isn't just about crushing—it’s about crushing wisely. By preventing up to 50% of crusher efficiency loss through robust iron removal practices, recyclers can extend equipment lifespan, reduce unscheduled downtime, and ensure a smoother, safer operation. Every bolt or rebar extracted early is a step toward greater sustainability and smarter site management.

Crush Waste, Build Smart: Embracing Circular Economy with Granite Recycling

In an age where sustainability is no longer a choice but a necessity, industries are continuously seeking innovative solutions to minimize waste and enhance resource efficiency. One powerful approach gaining traction is the use of on-site granite crushing to promote a circular economy. This method not only tackles the challenge of granite waste but also transforms it into a valuable resource, closing the loop of material use and reducing the environmental footprint of construction projects.

The Environmental Impact of Granite Waste

Challenges of Traditional Granite Disposal

Granite, with its durability and strength, is a popular choice for construction and decorative purposes. However, the cutting, shaping, and demolition of granite structures result in substantial waste. Traditionally, this waste has been sent to landfills, contributing to environmental degradation. The sheer volume of discarded granite, coupled with the difficulty of recycling it through conventional methods, creates a significant ecological burden. Landfills are rapidly reaching capacity, and the inert nature of granite means that it remains in these sites for decades, contributing to environmental concerns without decomposing. Additionally, transporting granite waste to distant disposal sites adds to the carbon footprint, exacerbating the environmental impact. As the construction industry continues to expand, addressing the issue of granite waste has become increasingly critical.

On-Site Granite Crushing: A Game-Changer

On-site granite crushing offers a transformative solution to the problem of waste management. By employing mobile stone crusher plant, construction sites can process granite waste right where it is generated. This approach not only reduces the volume of material sent to landfills but also converts it into reusable aggregate. The process of on-site crushing involves breaking down large chunks of granite into smaller, manageable sizes. These crushed materials can then be used as base material for new construction projects or as sub-base layers in road construction. This innovative practice not only diverts waste from landfills but also reduces the need for new raw materials, thereby lowering transportation costs and minimizing the overall environmental impact.

Advantages of Embracing a Circular Economy

Economic and Environmental Benefits

Adopting a circular economy approach through on-site granite crushing offers substantial economic and environmental benefits. Economically, using crushed granite on-site reduces the need for purchasing new aggregate, which can be a significant cost-saving measure for construction projects. By reusing the material, companies also minimize disposal fees and reduce the environmental impact associated with transporting waste to landfills. Environmentally, the circular economy approach minimizes resource extraction and decreases the carbon footprint associated with manufacturing new aggregate. The reduction in transportation emissions, combined with decreased demand for virgin materials, supports broader sustainability goals. Additionally, processing granite on-site helps conserve energy, as the crushing process is often less energy-intensive compared to transporting and processing materials off-site.

Enhancing Resource Efficiency and Project Sustainability

On-site granite crushing promotes resource efficiency by ensuring that materials are continuously cycled through the construction process rather than discarded. This efficient use of resources aligns with the principles of sustainability, supporting a reduction in overall waste and fostering a more responsible approach to material management. Projects that incorporate on-site granite crushing also benefit from improved operational efficiency. The ability to process and reuse materials directly on-site streamlines project workflows and reduces delays associated with waiting for new materials. This efficiency enhances project timelines and contributes to overall cost savings.

In summary, on-site granite crushing is a pivotal strategy in embracing a circular economy, effectively reducing waste and enhancing resource efficiency. By addressing the challenges associated with traditional granite disposal and leveraging the benefits of on-site processing, the construction industry can make significant strides toward sustainability. This approach not only conserves resources and minimizes environmental impact but also supports the development of more responsible and efficient construction practices.

Mobile Granite Crushing: Which Crusher Type Delivers the Best Results?

Granite's reputation as one of the hardest natural stones presents unique challenges for mobile crushing operations. The optimal granite crusher machine must balance production efficiency, particle shape requirements, and mobility constraints while withstanding the material's extreme abrasiveness. Three primary mobile crusher types—jaw, cone, and impact—each offer distinct advantages for granite processing, but their performance varies significantly based on operational parameters and final product specifications.

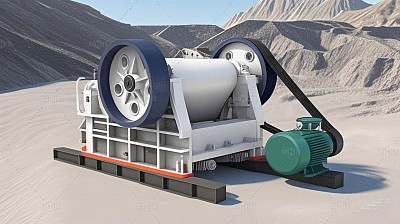

Jaw Crushers: The Primary Crushing Powerhouses

For initial granite size reduction, mobile jaw crushers deliver unparalleled performance in breaking down large blocks. Their robust construction and simple mechanical operation make them ideal for handling granite's high compressive strength. Modern mobile jaw units feature hydraulic adjustment systems that enable quick setting changes to optimize output size without stopping production.

The latest models incorporate wear-resistant alloys in jaw plates that extend service life by 40-50% compared to standard manganese steel. However, jaw crushers typically produce more elongated particles, which may require secondary processing for certain applications. Their true value emerges in high-volume primary crushing scenarios where reliability and throughput outweigh particle shape considerations.

Cone Crushers: Precision in Secondary Crushing

When cubical end products are essential, mobile cone crushers excel at granite processing. Their interparticle crushing action creates superior particle shape while maintaining high production rates. Advanced models feature automatic setting regulation that compensates for liner wear, ensuring consistent output quality throughout the wear cycle.

Modern mobile cone units offer multi-zone crushing chambers that optimize performance for different granite characteristics. The ability to switch between different chamber configurations makes them versatile for varied project requirements. Their main limitation lies in higher initial costs and more complex maintenance requirements compared to jaw crushers, but these are often offset by reduced downstream processing needs.

Impact Crushers: The Shape Specialists

For contractors prioritizing particle shape above all else, mobile impact crushers present a compelling solution. Their high-speed rotor systems fracture granite along natural cleavage planes, producing the most cubical end products. Recent technological advancements have addressed historical wear issues through composite alloy blow bars and rotor protection systems that extend component life in abrasive granite applications.

The latest generation incorporates adjustable grinding paths and hydraulic apron settings that allow operators to fine-tune output with precision. While impact crushers typically have higher wear costs than jaw or cone options, their ability to produce specification-ready material in a single pass often justifies the additional expense, particularly for high-value aggregate products.

Selecting the Optimal Solution

The ideal mobile granite crusher depends on a matrix of factors including production requirements, final product specifications, and operational constraints. For large-scale operations processing raw granite blocks, a jaw-and-cone combination often delivers the best balance of productivity and quality. Projects requiring premium-shaped aggregates may justify impact crusher investments despite higher wear costs. Ultimately, the crusher that delivers the best results is the one whose capabilities align most closely with the project's technical and economic parameters.

5 Ways a Track Crusher Adapts On-Site Without Extra Support Equipment

Modern track-mounted crushers have evolved into self-sufficient processing centers that eliminate the need for auxiliary equipment traditionally required in crushing operations. These standalone track crushers incorporate intelligent engineering solutions that allow them to adapt to varying site conditions, material characteristics, and production demands without relying on additional machinery. This independence translates to significant cost savings, operational flexibility, and faster project mobilization—key advantages in today's competitive construction environment.

Self-Contained Material Handling System

Track crushers integrate multiple material processing functions into a single chassis, eliminating the need for separate loaders and feeders. The onboard vibrating grizzly feeder with automatic bypass capability adjusts to uneven feed conditions, preventing bridging and ensuring consistent material flow. Hydraulic folding side conveyors create complete stockpiling systems without requiring additional stacking equipment. This integrated approach reduces setup space requirements by 40-50% compared to traditional crushing spreads while maintaining full processing capacity.

Advanced models feature load-sensing feed systems that automatically regulate crusher intake based on real-time power draw and chamber pressure. This intelligent material management prevents both underfeeding and overload conditions that would typically require operator intervention or equipment adjustments. The system's ability to handle unprocessed raw material directly from haul trucks or excavators further reduces dependency on support machinery.

Automatic Terrain Compensation Technology

The track-mounted design's true innovation lies in its adaptive mobility system that compensates for challenging ground conditions without additional grading equipment. Independent track drives with pressure-sensitive suspension automatically adjust to maintain stability on slopes up to 15 degrees—a capability that would normally require extensive site preparation with dozers. The aggregate crusher's weight distribution system dynamically shifts operational loads to prevent ground compaction issues in soft soil conditions.

Smart leveling technology takes this further by automatically adjusting the crusher's operating angle during production. As material processes through the chamber, hydraulic rams continuously compensate for minor settling or movement, maintaining optimal crushing geometry. This eliminates the production pauses typically needed to reposition stationary crushers or adjust support equipment. The system's terrain memory function even recalls ideal operating positions when returning to previously used locations.

Onboard Screening and Closed-Circuit Capability

Contemporary track crushers incorporate multi-stage screening systems that eliminate the need for separate screening plants. The hybrid screening design combines traditional vibrating decks with innovative air separation technology to achieve precise product classification. Operators can toggle between open and closed-circuit configurations with touchscreen controls, adjusting product specifications without physical reconfiguration.

The closed-circuit system's recirculating conveyor features automatic load balancing that prevents belt overloading—a common issue requiring additional monitoring equipment in conventional setups. Integrated metal detectors and automatic release mechanisms protect the crusher from tramp iron without needing separate magnetic separators. Some advanced models even include onboard washing systems that process manufactured sand to specification, replacing standalone washing plants for many applications.

These five autonomous capabilities transform track crusher equipment from simple processing units into complete material management systems. By consolidating functions that traditionally required multiple machines, they reduce fuel consumption by 35-45%, lower labor requirements by 50-60%, and decrease mobilization time by 75% compared to conventional crushing spreads. This operational independence proves particularly valuable in remote locations, urban job sites with space constraints, and projects requiring frequent relocation—situations where support equipment logistics would normally create bottlenecks. The track crusher's ability to adapt on-site without assistance represents not just an equipment improvement, but a fundamental shift in how the industry approaches material processing efficiency.

Built to Recycle: The Special Design Features of Mobile Impact Crushers for C&D Waste

The recycling of construction and demolition (C&D) waste presents unique challenges that conventional crushers simply aren't engineered to handle. Mobile impact crushers designed specifically for recycled materials incorporate specialized features to manage inconsistent feed composition, contaminants, and variable material densities. These machines transform mixed debris into high-quality aggregates through intelligent engineering solutions that address the three critical phases of C&D recycling: material intake, selective crushing, and contamination removal.

Intake and Pre-Sorting Systems

Unlike quarry crushers processing uniform feed, C&D units require robust material handling systems capable of managing everything from concrete chunks to wood scraps. Advanced models feature extra-wide feeder openings (up to 1.5m) with stepped grizzly bars that sift out oversized non-processables. Electromagnetic head pulleys automatically remove rebar and other ferrous metals during feeding, while impact-resistant chain curtains prevent flyback of lighter materials.

The most innovative systems incorporate AI-powered optical sorters that identify and reject non-mineral waste before it enters the crushing chamber. These vision systems can distinguish between concrete, brick, wood, and plastics with 95% accuracy, reducing contamination that would otherwise degrade end-product quality. Variable speed feeders automatically adjust throughput based on material density, preventing chamber overload when processing lightweight debris.

Impact Crushing Adaptations

The heart of these machines - the impact rotor - undergoes significant modifications for recycling duty. Extra-heavy rotors (up to 30% more mass than quarry models) maintain momentum when hitting irregular concrete chunks. Quick-change wear parts with tungsten carbide inserts withstand the extreme abrasion of mortar and brick components. Some models feature dual-purpose rotors that can switch between rock-on-rock and rock-on-steel crushing modes depending on material characteristics.

Unique chamber designs incorporate impact aprons with adjustable grinding paths that optimize for either concrete liberation or asphalt recycling. Hydraulic apron adjustment allows operators to fine-tune product gradation without stopping production - critical when processing mixed loads. Advanced vibration monitoring systems detect non-crushable objects and automatically reverse the rotor to eject them before damage occurs.

Integrated Contaminant Management

Post-crushing separation systems set recycling impact crushers apart from conventional models. Air classifiers remove lightweight contaminants like wood and plastics through controlled airflow, while vibrating screens with stepped deck designs separate fines containing gypsum and other undesirable components. Some units incorporate water spray bars that help separate paper and other hydrophilic materials from aggregate.

The latest generation includes onboard washing systems that scrub recycled aggregates, removing mortar residues and improving particle shape. These closed-loop water systems recover 90% of process water while filtering out suspended solids. For final quality assurance, metal detectors scan the product stream and automatically divert any remaining metallic contaminants.

These specialized features collectively enable mobile impact crushers to achieve 85-95% material recovery rates from mixed C&D waste - a dramatic improvement over the 60-70% typical of conventional crushing setups. The economic benefits compound through reduced landfill fees, premium pricing for clean recycled aggregates, and the ability to process materials on-site where space constraints prohibit traditional recycling methods. As circular economy principles gain traction in construction, these purpose-built recycling crushers are recycling construction waste streams into valuable resources one mobile operation at a time.

Crushing for Infrastructure: How Gravel Crushers Build Strong Foundations

The backbone of modern infrastructure—roads, bridges, and rail networks—relies on precisely engineered aggregate materials that meet exacting specifications for durability, drainage, and compaction. Gravel crushers serve as the unsung heroes of this process, transforming raw quarry stone and recycled materials into the graded aggregates that form the literal foundation of civil engineering projects. Their ability to produce materials with tightly controlled particle size distribution and fracture characteristics directly impacts the longevity and performance of infrastructure assets.

Precision Gradation for Structural Integrity

High-performance gravel crushers excel at producing aggregates with interlocking particle geometries that enhance load-bearing capacity. Modern cone crushers with adjustable eccentric throws create cubical particles ideal for base layers, while impact crushers generate the angular fragments needed for superior asphalt bonding. The latest models incorporate:

Laser particle analyzers that monitor gradation in real time

Automated gap adjustment maintaining ±2% consistency in product sizing

Multi-stage crushing chambers producing 4-5 specification products simultaneously

These capabilities prove critical when producing materials for heavy-use infrastructure. A 2% deviation in particle size distribution can reduce road base compaction by 15%, leading to premature surface failures. Quarry Crushers with closed-loop control systems prevent such variances, ensuring every ton meets DOT and ASTM specifications.

Material Innovation Through Advanced Crushing

The transition from simple size reduction to engineered aggregate production has redefined crusher technology. Selective crushing techniques now allow single plants to produce:

Porous asphalt aggregates with 25-35% void spaces for stormwater management

High-friction surface treatments meeting FHWA safety standards

Railroad ballast with optimal angularity indices for track stability

Advanced wear materials extend component life when processing abrasive volcanic rock or granite, with ceramic-impregnated liners lasting 3x longer than standard manganese steel in high-silica applications. Some operations now employ AI-driven crushing optimization that adjusts parameters based on real-time material analysis, consistently producing superior aggregates regardless of feed variations.

Sustainability in Infrastructure Materials

Modern gravel crushers contribute directly to sustainable construction practices through:

Recycled Material Processing

Today's plants routinely incorporate 30-50% recycled concrete and asphalt into new infrastructure projects without compromising quality. Advanced sorting systems remove deleterious materials while mobile impact crusher fracture reclaimed concrete along cement paste boundaries, producing clean aggregate.

Energy-Efficient Operations

Hylectric (hybrid-electric) crushers reduce energy consumption by 35-45% compared to conventional diesel-hydraulic units. Their regenerative braking systems recover kinetic energy during operation, while smart load management prevents power waste during partial capacity runs.

On-Site Production Advantages

Mobile crushing plants eliminate thousands of truck miles per project by processing materials at the construction site. A single highway project can reduce its carbon footprint by 400-600 tons of CO2 through localized crushing versus centralized plant supply.

The evolution of gravel crushing technology has made it possible to build infrastructure that lasts decades longer than previous generations of roads and bridges. As material science advances and sustainability requirements tighten, aggregate crushers will continue to play a pivotal role in transforming raw stone into the engineered foundations of our built environment. Their ability to balance precision, productivity, and environmental responsibility makes them indispensable tools for building the resilient infrastructure systems of tomorrow.

Forecasting 2025-2030: How Global Trends Will Affect Concrete Crusher Machine Prices

The concrete crusher market stands at an inflection point, with macroeconomic, technological, and regulatory forces converging to reshape equipment pricing structures. Between 2025-2030, crusher manufacturers will navigate a complex landscape of material cost volatility, decarbonization mandates, and shifting regional demand patterns—all of which will influence machine affordability and total cost of ownership. Understanding these interconnected factors enables smarter capital allocation for contractors planning fleet upgrades or expansions.

Raw Material Economics and Manufacturing Costs

Commodity price fluctuations will disproportionately impact crusher production expenses:

Steel alloys (comprising 60-70% of crusher mass) face 8-12% annual price hikes due to green steel transition costs

Copper wiring and electric components for smart crushers may see 15-20% increases as renewable energy projects consume supplies

Rare earth elements in permanent magnet motors could become 30-50% more expensive with EV market competition

These input costs will drive base concrete crusher machine price upward by 4-6% annually, though manufacturers may offset increases through:

Modular designs reducing steel content in non-critical components

Remanufactured exchange programs for wear parts

Localized production avoiding tariff impacts on finished goods

Decarbonization Regulations and Technology Premiums

Stringent emissions standards will bifurcate the crusher market into two pricing tiers:

Legacy Diesel Models

Facing 18-22% price inflation from 2025 onward due to:

Carbon border adjustment taxes in Western markets

Aftertreatment system requirements (DPF+SCR) adding $28,000-$45,000 per unit

Progressive bans in urban centers reducing resale value

Electric/Hybrid Crushers

Commanding 25-30% premiums initially, though stone crusher plant price will stabilize by 2028 as:

Battery pack costs decline below $100/kWh

Standardized quick-change battery systems emerge

Renewable microgrids reduce infrastructure dependency

The total cost equation will increasingly favor electric models—projected to achieve parity with diesel by 2027 when factoring in fuel and maintenance savings.

Regional Demand Shifts and Supply Chain Realignment

Geopolitical and infrastructure trends will create pricing disparities across markets:

RegionPrice Projection 2025-2030Key InfluencersNorth America+5.5% CAGRInflation Reduction Act subsidies, nearshoringEU/UK+7.2% CAGRCarbon pricing, skilled labor shortagesSoutheast Asia+3.1% CAGRChinese OEM competition, local content rulesMiddle East+4.8% CAGROil revenue investments, desalination costs

The used equipment market will expand significantly as Western contractors upgrade to compliant models, creating a 35-40% discount channel for price-sensitive buyers in developing markets. However, these secondary units may lack compatibility with region-specific automation and telematics standards.

Strategic buyers should monitor three indicators when timing purchases: lithium battery cost curves, Basel Convention amendments on equipment exports, and regional infrastructure bill passage. Those who align acquisitions with these milestones can secure 15-20% better pricing than market averages while future-proofing their operations against regulatory and technological obsolescence. The coming decade will reward contractors who view crusher procurement not as simple equipment replacement, but as strategic positioning within a transforming industry ecosystem.

Which Crusher Should You Choose For Primary Crushing? Types Of Primary Crushers

Selecting the right primary crusher is the cornerstone of any efficient aggregate processing operation. This critical decision impacts everything from production capacity and energy consumption to final product gradation and maintenance costs. With multiple crusher machine types available—each excelling in specific material reduction scenarios—understanding their fundamental operating principles and ideal applications separates profitable operations from underperforming setups.

The primary crushing stage serves as the first line of defense against oversized material, reducing quarry-run stone to manageable sizes for downstream processing. Modern crushers have evolved beyond simple compression machines into sophisticated systems incorporating impact, shear, and attrition forces. What follows is a detailed examination of the three dominant primary crusher categories, their operational nuances, and how to match them to your specific raw material characteristics and production goals.

Jaw Crushers: The Workhorse of Primary Crushing

Renowned for their robust construction and straightforward operation, jaw crushers dominate primary reduction circuits for good reason. Their toggle-activated compression mechanism creates a predictable elliptical motion that efficiently fractures even the most abrasive materials. Modern designs feature hydraulic adjustment systems allowing operators to modify closed-side settings in seconds—a crucial advantage when processing variable feed materials.

The true brilliance of jaw crushers for sale lies in their ability to handle unprepared feed containing moderate fines without choking. This makes them ideal for operations dealing with blasted quarry rock where particle size distribution varies widely. Advanced models now incorporate load-sensing hydraulics that automatically reduce crushing force when encountering uncrushable objects, significantly decreasing tramp metal damage incidents.

Gyratory Crushers: High-Capacity Precision Reduction

When throughput requirements exceed 1,000 tons per hour, gyratory crushers emerge as the undisputed champions. Their distinctive mantle-spider assembly creates a progressive crushing action that continuously reduces material as it moves downward through the chamber. This results in superior product shape compared to jaw crushers, particularly important when producing aggregate for asphalt or high-grade concrete.

Modern gyratory crushers feature intelligent wear compensation systems that automatically maintain crushing gaps as manganese liners wear. Some premium models incorporate rotating eccentric bushings that can adjust crusher settings during operation—eliminating downtime for manual adjustments. Their only notable limitation is sensitivity to flat or elongated feed material, which can cause bridging in the crushing chamber.

Impact Crushers: When Shape Matters Most

For operations prioritizing product cubicity over maximum reduction ratios, horizontal shaft impact crushers (HSIs) offer compelling advantages. Their hammermill-style reduction produces consistently angular aggregate ideal for asphalt and road base applications. Recent technological advancements have expanded their capabilities into harder rock categories previously reserved for compression crushers.

The latest generation of HSIs features adaptive rotor systems that automatically adjust breaker plate clearances based on real-time feed analysis. This maintains optimal reduction efficiency despite variations in material hardness or moisture content. Some models incorporate dual-function rotors that can switch between shoe-and-anvil and shelf-on-shelf configurations mid-operation—a game-changer for contractors processing diverse material streams.

Each crusher type brings distinct advantages that align with specific production requirements and material characteristics. Jaw crushers remain the most versatile option for general applications, while gyratory crushers excel in high-tonnage scenarios. Impact crushers shine when product shape is paramount. The wisest selection strategy involves analyzing not just initial cost, but total cost of ownership including energy consumption, wear part longevity, and maintenance complexity over the equipment's operational lifespan.

All-in-One Mobile Crusher Solution: The Benefits of Integrated Crushing, Screening, and Feeding Systems

The construction and mining industries demand efficiency, flexibility, and sustainability—qualities that traditional multi-stage crushing setups often struggle to deliver. Enter the all-in-one mobile crusher, a revolutionary approach that consolidates crushing, screening, and feeding into a single, highly mobile unit. By eliminating the need for multiple machines and complex logistics, these integrated systems are transforming material processing, offering unparalleled convenience and performance.

The Evolution of Crushing Technology

From Fragmented Systems to All-in-One Solutions

Historically, material processing required separate machines for crushing, screening, and conveying—each adding layers of complexity, maintenance, and cost. Operators had to coordinate between equipment, manage additional fuel consumption, and contend with logistical bottlenecks. Modern all-in-one crushers consolidate these functions into a singular, streamlined apparatus, drastically reducing setup time and operational friction.

How Integration Enhances Operational Efficiency

By unifying these processes, integrated mobile crushers minimize transitional delays between crushing and screening. Material flows seamlessly through the system, reducing idle time and maximizing throughput. Advanced automation ensures precise control over particle size distribution, eliminating the guesswork associated with traditional setups. The result? Faster project completion and consistent output quality.

Key Advantages of Integrated Mobile Crushers

Seamless Material Processing with Combined Crushing and Screening

The hallmark of these systems is their ability to crush, screen, and even feed material in a continuous loop. Whether processing demolition debris or quarry rock, the integrated screening mechanism allows for immediate classification of aggregates. Oversized material can be recirculated for further reduction, while properly sized output is ready for use—no secondary handling required.

Reduced Operational Costs and Footprint

Fewer machines mean lower fuel consumption, reduced maintenance expenses, and minimized labor requirements. Contractors no longer need to invest in multiple pieces of equipment or allocate extensive space for setup. The compact design of all-in-one crushers makes them ideal for constrained urban job sites or remote locations where space is at a premium.

Enhanced Mobility for Diverse Job Sites

Unlike stationary plants, mobile aggregate crushers can be rapidly deployed and repositioned as project demands shift. Many models feature track-mounted mobility, enabling easy relocation without disassembly. This agility is particularly beneficial for short-term contracts, road construction projects, or recycling operations where materials must be processed on-site.

Applications and Industry Impact

Ideal for Fast-Paced Construction and Demolition Projects

In demolition and recycling, time is of the essence. Integrated crushers allow contractors to process concrete, asphalt, and masonry debris directly at the source, reducing hauling costs and landfill dependency. The ability to produce reusable aggregates on-site supports circular economy principles, turning waste into valuable resources.

Sustainable Benefits: Lower Emissions and Energy Consumption

Consolidating multiple functions into one machine reduces the carbon footprint associated with material processing. Fewer machines operating simultaneously translate to lower emissions, while optimized power usage ensures energy efficiency. Some models even incorporate hybrid or electric drive options, further minimizing environmental impact.

The shift toward all-in-one mobile track crusher reflects a broader industry trend favoring efficiency, sustainability, and adaptability. By integrating crushing, screening, and feeding into a single unit, these systems eliminate inefficiencies, cut costs, and enhance productivity—making them indispensable for modern construction, mining, and recycling operations. As technology advances, their role in shaping a more streamlined and eco-conscious industry will only grow more pronounced.

Crushing and Grinding Limestone: The Complete Crusher Machine Lineup for Powder Plants

Limestone forms the backbone of countless industries, from construction to agriculture, yet its journey from quarry to powder is anything but simple. Transforming rugged stone into fine, consistent powder demands precision machinery capable of handling various stages of size reduction. Modern powder plants rely on a carefully orchestrated lineup of limestone crusher and grinders, each designed to tackle specific particle size requirements while optimizing energy efficiency. Understanding this equipment hierarchy—from primary crushing to final micronization—reveals how raw limestone metamorphoses into the high-quality powders driving industrial processes worldwide.

Primary Crushing: The First Reduction

Every limestone processing operation begins with primary crushing, where massive chunks extracted from quarries undergo initial size reduction. Jaw crushers dominate this stage, their robust frames and powerful compressive forces breaking down meter-sized boulders into manageable 6-8 inch fragments. What makes modern jaw crushers exceptional is their adjustable crushing chamber, allowing operators to fine-tune output size while minimizing energy waste. Some advanced models incorporate hydraulic tensioning systems that automatically compensate for wear, maintaining consistent performance throughout thousands of crushing cycles.

For operations prioritizing mobility, track-mounted primary crushers bring unprecedented flexibility. These self-contained units can relocate across quarry faces or between sites, processing limestone at the source rather than hauling unprocessed material. Their integrated pre-screening capabilities bypass already-sized material, boosting overall efficiency by 15-20%. Whether stationary or mobile, primary jaw crushers set the foundation for downstream processing by producing uniformly fractured stone ready for secondary reduction.

Secondary and Tertiary Crushing: Refining the Product

Once primary crushing concludes, cone crushers and impactors take center stage. Cone crushers operate on the principle of gyratory compression, their mantle and concave liners progressively crushing limestone into cubical aggregates ranging from ¾ inch to 2 inches. Modern hydrocone designs feature automated control systems that monitor and adjust crusher parameters in real-time, ensuring optimal performance while protecting against mechanical overloads.

For applications requiring finer intermediate products, vertical shaft impactors (VSIs) deliver unparalleled particle shaping. By accelerating limestone particles at high velocities against anvils or rock shelves, VSIs produce uniformly graded material with excellent cubicity—a critical characteristic for powder plants targeting specific bulk densities. Some tertiary crushing circuits incorporate air classifiers that simultaneously separate fines, routing them directly to final grinding while returning oversize material for additional crushing. This closed-loop approach maximizes yield while minimizing energy-intensive regrinding of already-spec material.

Fine Grinding: Achieving Powder Perfection

The transition from crushed aggregate to powder occurs in grinding mills, where limestone undergoes its final metamorphosis. Ball mills have long been the workhorses of this stage, their rotating drums filled with grinding media reducing particles to 100-200 mesh sizes. However, modern powder plants increasingly adopt vertical roller mills for their superior energy efficiency. These mills employ hydraulically-loaded rollers that grind limestone against a rotating table, with integrated classifiers immediately separating particles that meet target fineness.

For ultra-fine applications demanding particles below 10 microns, stirred media mills take grinding technology to its zenith. Utilizing high-speed rotors that agitate grinding beads, these mills achieve particle sizes impossible with conventional equipment. Advanced versions feature cryogenic grinding capabilities for heat-sensitive limestone derivatives, preserving chemical composition while attaining sub-micron distributions. Throughout all grinding stages, automated particle size analyzers and PLC systems maintain tight quality control, ensuring each powder batch meets exacting industry specifications.

From quarry to powder silo, the impact crusher and grinder lineup forms an interconnected ecosystem where each machine’s performance impacts the next. Contemporary powder plants don’t just crush and grind—they intelligently adapt to material characteristics, optimize energy use, and produce consistent powders that meet increasingly stringent industrial requirements. As sustainability demands grow, this equipment lineage continues evolving, blending raw processing power with precision control to transform ancient limestone into tomorrow’s essential powders.